Expanding the scope of your team.

Five Ways an Outside Partner Can Bring Clarity and Value to Your Next Extrusion-Based Project

By Jason Lang, Vice President

Producing food—whether for animal or human consumption—has never been more complex.

We work in an industry under scrutiny by regulators and the public over safety concerns. Consumers are hypervigilant about the ingredients they’re feeding their pets. We share a looming responsibility to meet the nutrition demands of a world population that’s growing exponentially.

From this storm of dynamics, the pet food industry has emerged more focused than ever on food safety and better nutrition and ingredients. The good news is advancements in food production allow development of formulations to improve animal health, keep food products safe from contamination throughout the process, and produce food more efficiently to meet growing production demands.

This is all great news for an industry facing serious challenges. But, as we discussed in our previous article, those advancements come with more complex processes and require sophisticated factory designs, and this can be intimidating when you’re the one leading the charge.

In a regulatory environment that every year more closely mirrors the regulations of human food production, manufacturing companies need a partner who has the depth of knowledge to handle the entire scope of a project, including navigating the intricacies of food safety standards.

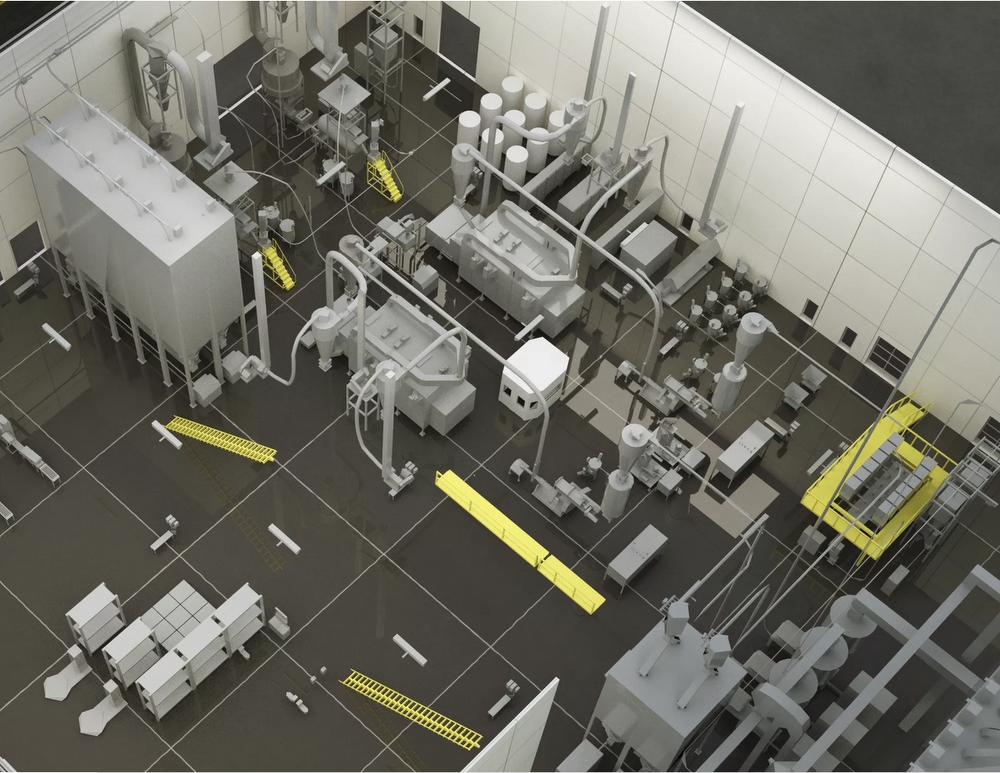

Corporate Project Services is an expert in extrusion-based technology, which manufacturers rely on to safely produce high quality food products and to do so efficiently. Whether your extrusion project is for pet food, aquafeed, or human food, manufacturers need a partner with the experience and expertise to help navigate a rapidly evolving and complex industry.

Below are five areas where an outside partner could guide your company through the complexities of today’s food manufacturing environment.

Resource allocation is often an issue with new plant installations because companies typically cannot afford to spin off their brightest people onto a multi-year special assignment. There’s great benefit in having an outsider’s perspective—such a partner can be your eyes and ears externally while you stay focused on internal priorities. By establishing a closely integrated working relationship with an outside partner, the client maintains oversight without the hassle and without internal resources getting monopolized with implementation. Having a dedicated team also speeds up timelines, so projects can reach completion faster than if they were driven by an internal team with competing priorities.

Helping you get the most from your investment.

You need a partner with the breadth of experience and know-how to customize a plan for your unique vision and goals. A good partner will weigh the pros and cons of various factory designs and equipment when formulating recommendations, but sometimes the model with the most “pros” exceeds budgetary constraints. That doesn’t have to prevent you from meeting your goals, however, and the right partner will optimize the design within the available budget and ensure you achieve the expected return on investment.

Gaining buy-in from internal stakeholders.

We see this scenario frequently: A company has massive production goals, and the best solution is to build a new factory. Selling the project internally is the first hurdle, and it’s overwhelming to figure out where to start. So many factors go into decision making when the stakes are this high, and your chances of getting approval are much better when you have the right information to justify the investment. How quickly will you get payback? What will the facility look like? What is the flow going to be? What does a day in the life of an operator look like? You want a partner who understands what decision makers need to know to buy in to the project—the needs of a CEO or CFO will be different than a R&D director, and your partner should be able to help you deliver that to whomever is sitting across the table.

Taking the concept to market.

The difference between success and failure often depends on the implementation, so bridging the gap between concept and contractor is critical to achieve a successful installation. The goal with any project should be to build a factory with minimal disruptions and change orders. That requires your partner to make sure what is detailed on paper is communicated concretely to the contractor and other collaborative vendors to ensure specifications on capacities, utilities and other pertinent details are understood by all involved parties. Having accurate information enables a sound bid from the very beginning so the project isn’t fraught with surprises and chaos.

Providing safety assurance.

Safety may be THE biggest issue on the table for food producers today. The right partner can help a company circumvent millions in losses in a factory by creating a food safe culture that is easy to manage and sustain for the long term. Also key is knowing how to conduct comprehensive food safety audits—preventing widespread downtime or even saving a factory from a complete shutdown.

You need a partner who can advise on better ways to automate processes so businesses can scale-up production without sacrificing quality and while still maintaining a safe and clean manufacturing environment. Your partner should be able to think through the situation to mitigate risks for all scenarios that could arise in a factory environment. (So, if a door accidentally gets left open on the 3rd shift, the manager can rest assured there will not be a recall because of an airflow issue.)

Finding the Right Expert

Food safety concerns brought on a new climate of intense scrutinization of factory operations, which in turn forced companies to take drastic measures to assure regulators and the public that their processes are safe. Manufacturing companies need a partner who’s been through all the scenarios, who can communicate effectively with every level and function in your organization, who can advise on all the nuances of safety, and who can collaborate with your internal team and your contractors to lead the project to fruition.

At Corporate Project Services, we’ve devoted our careers to this and can align anywhere your project calls for expert guidance. Collectively, our team has more than 120 years of experience in the industry with expertise in management, engineering, sales and international factory integration, all which give us unequaled know-how in project planning services. We are in the factories every day talking with industry experts about best practices. From cost analysis through implementation and everything in between, Corporate Project Services is equipped to be your partner every step of the way to ensure your project meets the design criteria and your unique objectives. If you have challenges you’d like to discuss with an outside expert, please reach out to our team and we’d be glad to help.

Corporate Project Services, a division of Wenger Manufacturing, is a dynamic group of planning specialists backed by Wenger’s more than 80 years of process system supply to the industry. Our knowledge base and breadth of experience in extrusion processing and facilities construction is unsurpassed – and our commitment to excellence is recognized around the world.

More Articles

Jan 08, 2021

•

10 Minute Read

Communication is Everyone’s Job

When was the last time you did a performance appraisal on your job as a communicator?

Read More

Jan 08, 2021

•

10 Minute Read

Communication is Everyone’s Job

When was the last time you did a performance appraisal on your job as a communicator?

Read More

Feb 08, 2020

•

10 Minute Read

Boosting Value in a Technical Manual

I can’t say I know anyone who would call an operations manual “riveting” or a “real page turner”—but here at Corporate Project Services we treat these resources as an opportunity to add value for our clients.

Read More

Feb 08, 2020

•

10 Minute Read

Boosting Value in a Technical Manual

I can’t say I know anyone who would call an operations manual “riveting” or a “real page turner”—but here at Corporate Project Services we treat these resources as an opportunity to add value for our clients.

Read More

Nov 19, 2019

•

10 Minute Read

Navigating the High Stakes and Complexities of Food Manufacturing

Ask anyone involved in food production to name the greatest challenge facing the industry today, and food safety is sure to top the list.

Read More

Nov 19, 2019

•

10 Minute Read

Navigating the High Stakes and Complexities of Food Manufacturing

Ask anyone involved in food production to name the greatest challenge facing the industry today, and food safety is sure to top the list.

Read More